The industrial processes for the production of cellulosic ethanol generate significant volumes of a lignin‐rich residue stream, which is normally combusted to produce heat and power, both for the plant’s needs and for grid injection.

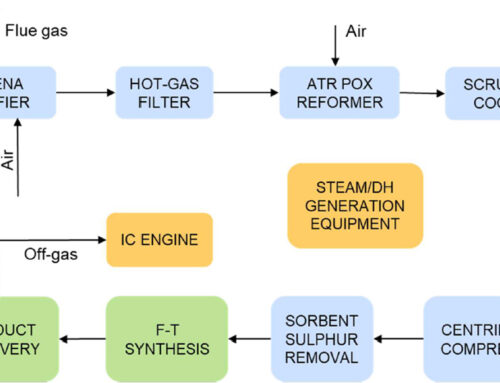

In BECOOL, an alternative solution to valorise the lignin-rich residue is being evaluated, by converting it into bio-oil, a liquid intermediate energy carrier, via fast pyrolysis (Fast Pyrolysis Bio-Oil or FPBO). During the fast pyrolysis process, gaseous and solid (char) by‐products are generated in addition to the FPBO. In commercial scale fast pyrolysis plants, these by‐products are combusted to generate heat and power for the pyrolysis plant while the surplus is exported as renewable energy. The concept evaluated within BECOOL is to replace the lignin combustor in ethanol plants with a fast pyrolysis process. Instead of excess electricity, lignin oil is produced as additional product. The FPBO can then be used for the production of biofuel through gasification or hydrotreating, or alternatively, as source of bio-based chemicals and materials. By applying this conversion pathway the lignin rich residues could potentially generate a much higher added value compared to the business as usual of combustion for combined heat and power.

In 2020, experimental trials for the conversion of the lignin‐rich residue of cellulosic ethanol plants into FPBO, were performed in the Netherlands by BTG. Due to the specific nature of the feedstock, some modifications to the standard process conditions of fast pyrolysis had to be elaborated and tested. As a result of the tests, the chemical pre‐treatment of the lignin-rich residue with calcium hydroxide proved to be a suitable solution to prevent any operational issues. The yield of pyrolysis oil was relatively high and with low water content, although this solution implies additional costs for the pre-treatment of the feedstock, compared to standard fast pyrolysis.

Further techno‐economic evaluations and different modelling of process option will be carried out this year, to obtain a complete overview of the possible integration of fast pyrolysis in the bioethanol production process.

The lignin‐rich residue during outdoor drying.

The bench‐scale pyrolysis setup ‘MPP’ in the BTG laboratory.